Industrial Optimization

Planification opérationnelle

Industrial optimization: a multi-faceted concept

At an abstract level, optimization means making the most of existing assets; by extension, it can also refer to the most profitable investments in new equipments or assets. This first distinction gives rise to 2 application horizons for optimization in industry: long-term structural optimization and short-term operations optimization.

Moreover, operations management itself can be addressed in a variety of ways, depending on whether the approach taken to refinery optimization is bottom-up, or top-down:

The special case of refinery operations

Our innovative approach to refinery optimization takes account of 2 crucial facts:

- Day-to-day operations are subject to uncertainty,

- Regardless of the inherent formal difficulty of achieving an overall refinery schedule optimization, an overall optimized schedule is of little use.

This is simply because an overall solution achieved that way is inherently unstable: the slightest change or unforeseen event means that the whole schedule must be rebuilt. And given the huge amount of inertia in such a large system, any sudden change of trajectory consumes an equally huge amount of energy.

Under this pragmatic perspective, refinery optimization appears as the search for a maintainable globally feasible, locally optimized schedule. Optimization is applied to sub-systems where a high economic impact is achievable.

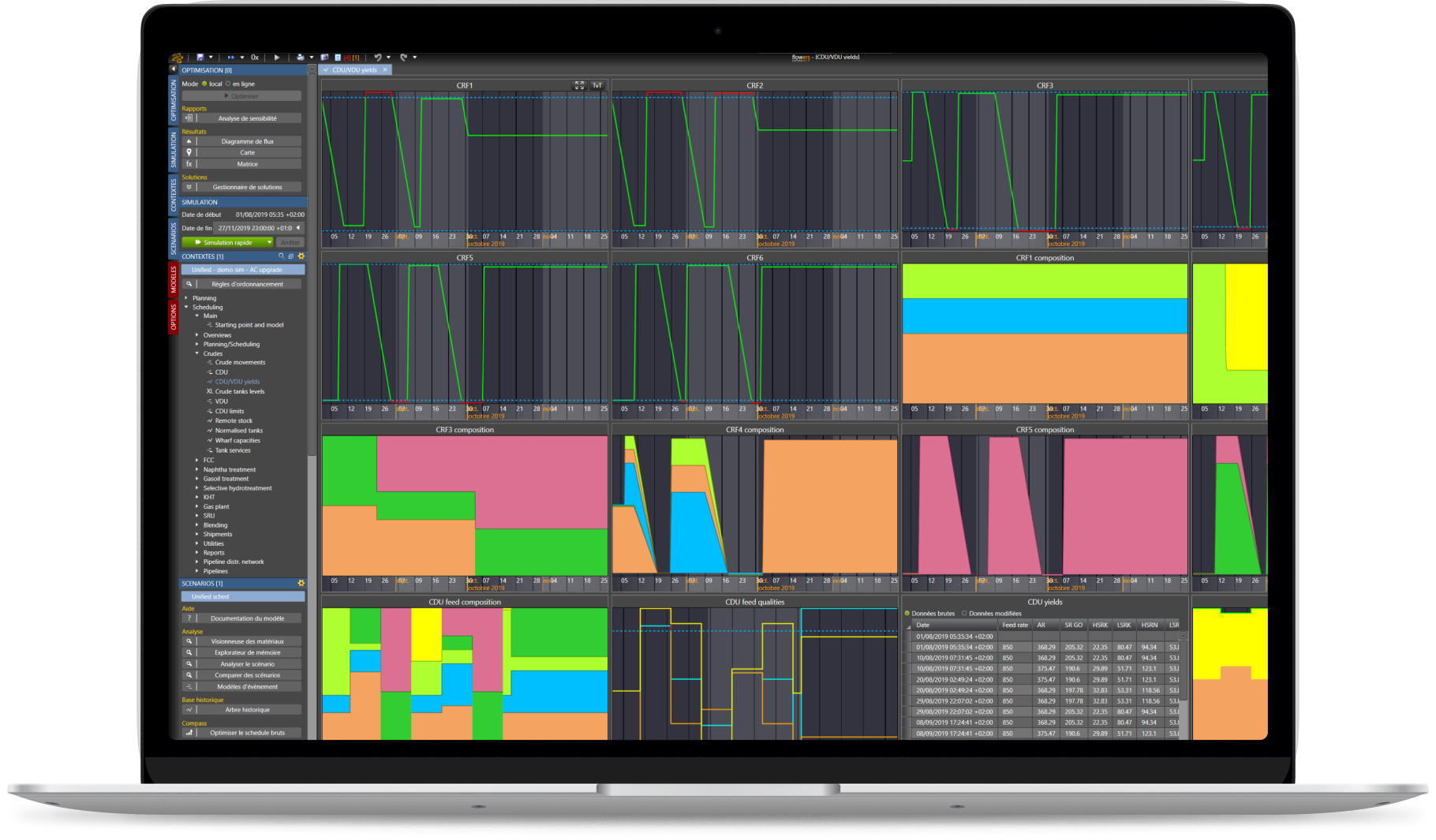

To be realistically achievable, effective and efficient, refinery optimization therefore should be considered as an orchestrated effort that needs to be put in practice under uncertain assumptions, and this approach should therefore provide the means to confidently and rapidly implement day-to-day adjustments to subsystems to achieve locally optimized schedules. PRINCEPS solutions materialize refinery optimization through a right combination of smart simulation and local optimization modules.