Prepare your master plan with peace of mind using our industrial planning tools

Develop your operational plan: ever simpler with the Flowers platform!

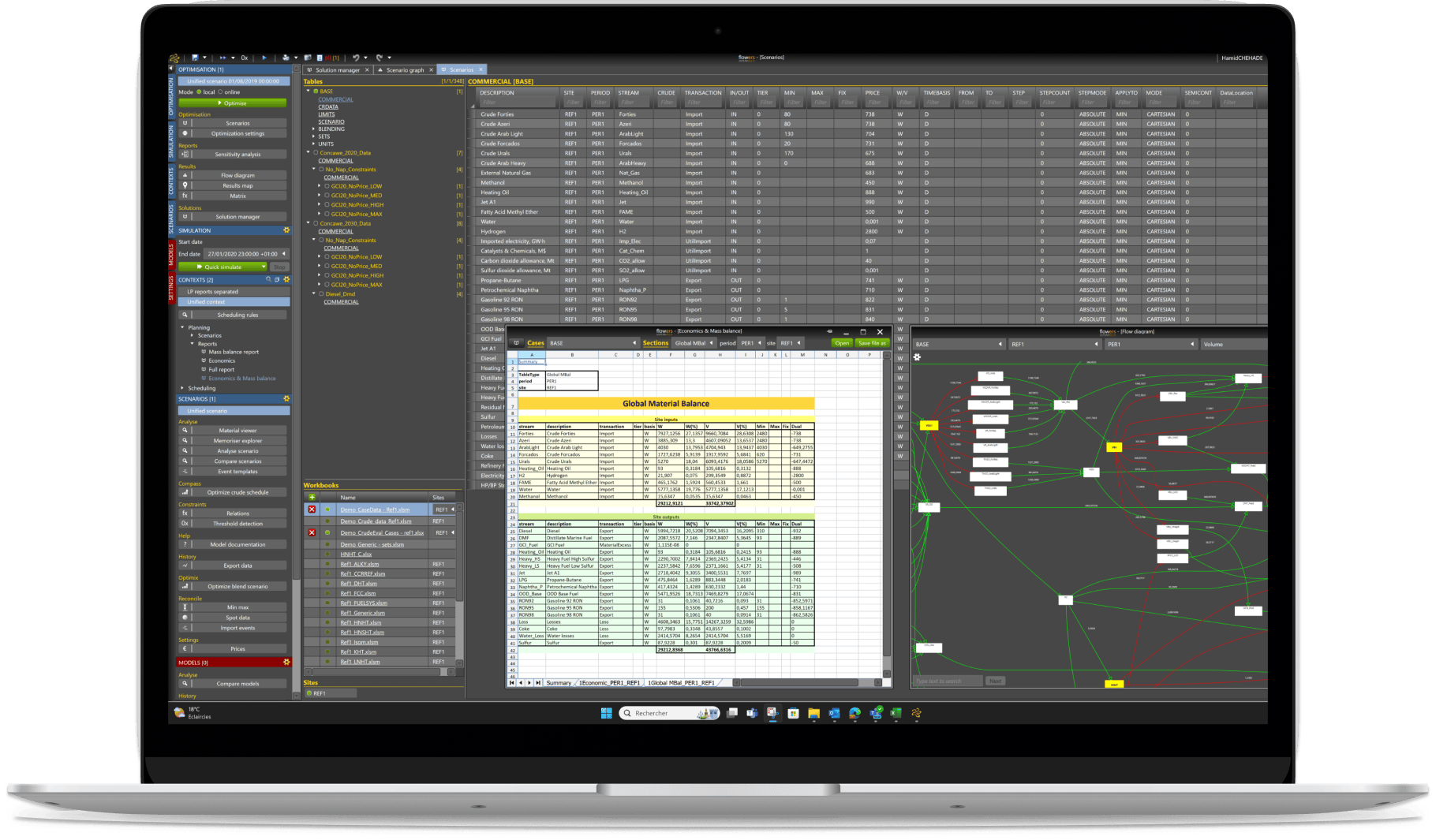

In the quest for rigorous production planning, the Flowers platform provides a planning module based on linear programming, the key to determining “the optimum combination of factors”: raw materials, products to be manufactured, operating conditions of production units. By taking into account operating costs, the price and availability of raw materials, plant capacity and market demand, this technique makes it possible to minimise costs or maximise profits.

Basically, linear programming consists of identifying a set of activities under the condition that no activity would be used if a more profitable activity (or combination of activities) were available. The scope of optimisation may include one or several sites, and the time horizon may comprise one or several periods. In addition, the method involves valuing the scarce resources (marginal costs) that define the opportunities available to the company.

Finally, the platform provides the tools needed for investment studies, enabling new processes to be selected on the basis of their optimum integration into the industrial layout and their synergy with existing processes. The tool can also be used to choose the optimum location for new processes in the case of a multi-site model.

The principles underlying the flowers planning module include the following elements:

Modelling

This involves transforming production problems into simplified mathematical models, where decision variables represent material flows, unit activities, quantities of products to be produced and constraints reflect capacity limits, raw material availability and market requirements.

Objective function

Maximising or minimising an objective function, which generally represents total profit or cost.

Optimal solutions

By solving the underlying mathematical model, flowers provides an optimal solution that describes the best combination of factors to maximise or minimise the objective function, while making efficient use of their resources.

Sensitivity analysis

Flowers can also perform a sensitivity analysis to assess the economic impact of changes in the model inputs, such as raw material costs, capacity or variations in demand.

Operational planning: what if you also take a look at marginal costs?

Marginal cost is a key economic concept that represents the additional cost incurred at the optimum when producing an additional unit of a product or service. In other words, it measures the change in total cost when production increases by a single unit.

Economic analysis of the solution in flowers: